Kaviri Mash mbiru matatu-mhedzisiro inosiyanisa kumanikidza distillation maitiro

Overview

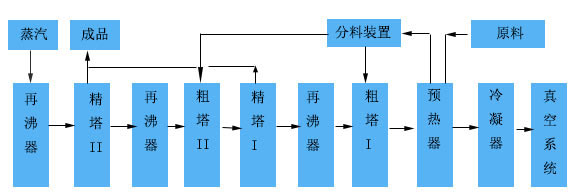

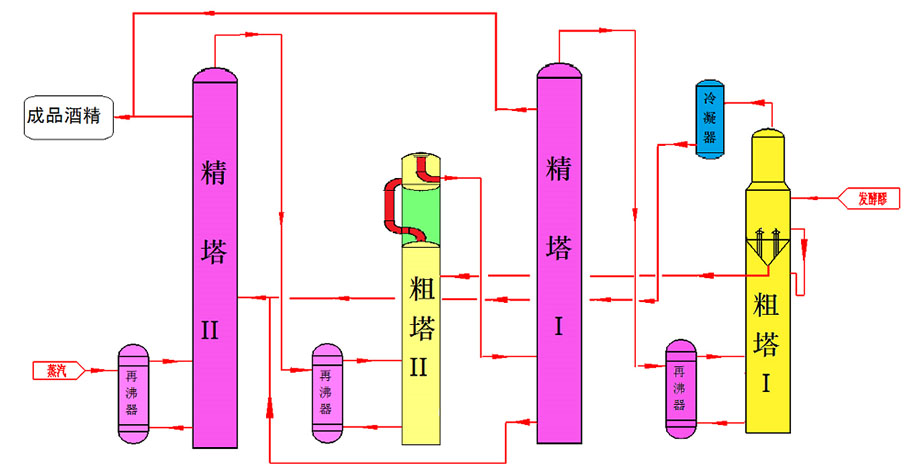

Iyo mbiri-column distillation kugadzirwa kweiyo general-giredhi yedoro process inonyanya kuumbwa neshongwe yakanaka II, iyo coarse tower II, yakakwenenzverwa shongwe I, uye yakakora shongwe I. Imwe system ine shongwe mbiri dzakakasharara, shongwe mbiri dzakanaka, uye imwe. shongwe inopinda muutsi shongwe ina. Iyo yekusiyanisa kudzvinyirirwa pakati peshongwe neshongwe uye mutsauko wekushisa unoshandiswa kuchinjanisa zvishoma nezvishoma kupisa kuburikidza neiyo reboiler kuzadzisa chinangwa chekuchengetedza simba. Mubasa racho, shongwe mbiri dzisina kuchena dzinodyiswa panguva imwe chete, uye shongwe mbiri dzakanaka panguva imwe chete dzinotora doro. Parizvino, maitiro aya akasimudzirwa mune dzakawanda-giredhi-giredhi doro uye mafuta ethanol vagadziri.

Chechitatu, maitiro maitiro

1. Kuderera kwesimba rekushandisa, 1.2 matani ekunwa doro.

2. Imwe mhute inopfuura nemu reboiler kuti inopisa shongwe yakanaka II, iyo yakanaka shongwe II yepamusoro mhepo yewaini inopisa shongwe isina kuchena II kuburikidza neiyo reboiler, iyo isina kuchena shongwe II mhute yepamusoro yewaini inopisa zvakananga shongwe yakanaka I, uye shongwe yakanaka I. tower top waini inopfuura nepakati Iyo reboiler inopisa iyo crude column I. Imwe shongwe inopinda mumhepo uye shongwe ina kuti iwane matatu-zvinoita kupisa kwekubatana kuwana simba rekuchengetedza.

3. Kushandisa kusiyanisa kudzvinyirirwa uye kusiyana kwekushisa pakati peshongwe neshongwe kuti zvishoma nezvishoma kuchinjana kupisa kuburikidza ne reboiler, kupisa kunogona kushandiswa kusvika pamwero mukuru, nokudaro zvinobudirira kuchengetedza simba.

Chechina, maitiro

shanu, kupisa nzira

Chinokosha chekuchengetedza simba kwemaitiro ndiyo nzira yekupisa. Iyo yekutanga steam inopisa zvisina kunanga neiyo reboiler kuchenesa shongwe II. Mvura yakanyungudutswa yeutsi inofashaidza yakura yekuvirisa mash uye crude alcohol yozodzokera ku boiler yemvura yakapfava tank kuti ishandiswezve; iyo yakanatswa shongwe II waini mhute inopfuura nepakati reboiler. Iyo crude column II inopisa; iyo yakanaka column I waini mhute inopiswa neiyo reboiler kune isina kuchena column I.

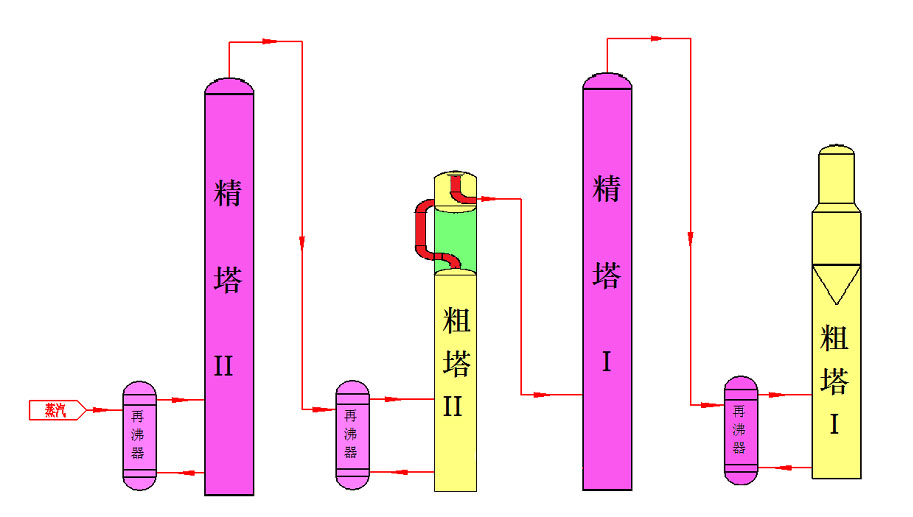

Mukuita uku, shongwe isina kusimba I ishongwe yekumanikidza yakaipa, iyo coarse shongwe II uye yakanaka shongwe Ini ndiri mumhepo yekumanikidza shongwe, uye iyo yakanaka shongwe II ishongwe yekumanikidza yakanaka. Musiyano wepressure uye musiyano wetembiricha unoshandiswa pakupisa nhanho. Imwe shongwe inopinda muutsi uye shongwe nhatu kuti iwane matatu-effect thermal coupling kuzadzisa zvinangwa zvekuchengetedza simba.

Yechitanhatu, mamiriro ezvinhu

Iyo nhanho mbiri preheated fermentation mash inotanga kupinda pamusoro peiyo crude column I kuti ibvise aldehyde, yobva yakamura mash muzvikamu zviviri kuburikidza nemugovera: chikamu chimwe chinopinda mucoarse column II, uye chimwe chikamu chinopinda mukoramu yakaoma I. . Mushure mokunge mash yakaviriswa inopinda mushongwe isina kuchena II, mvura yakashata inobviswa kubva pasi peshongwe, uye doro risina kuchena rinopinda mufaini. shongwe I kuti iomerwe uye ibudiswe, uye chikamu chedoro rakapedzwa rinotorwa kunze kwepamusoro mutsara weparutivi.

Mushure mepasi peshongwe yakacheneswa ndinorerutsira waini uye shongwe isina kuchena I pamusoro pewaini vapor condensate, inopinda mushongwe yakanaka II, inotarisa uye inobvisa mushongwe yakanaka II, uye inoburitsa imwe yedoro rakapedzwa mumutsetse wepamusoro weparutivi, uye yakakwira yekubikira tsvina yakadai semafuta efuseli Bvisa kubva pazasi peshongwe yakanaka II.

Zvinomwe, huwandu hwehuwandu hwekunwa doro uye tafura yekuenzanisa yemhando